Home > Test Stands > 87RM233 Stationary "UNIVERSAL" Wide Body Aircraft Components Test Stand

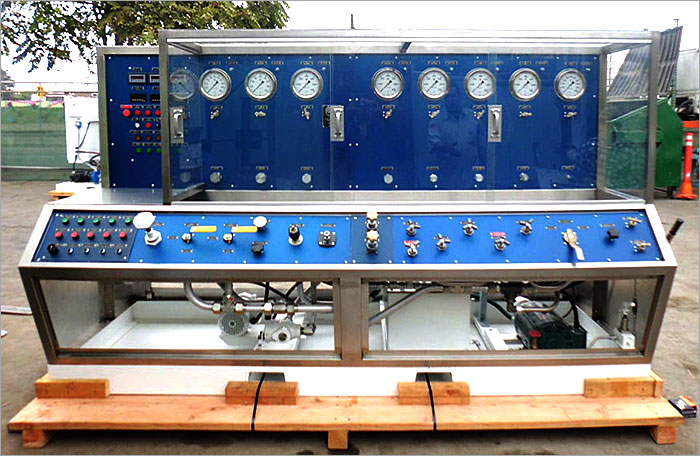

87RM233 Stationary "UNIVERSAL" Wide Body Aircraft Components Test Stand

| GPM/PSI: |

50 GPM @ 3000/5000 PSI |

|

|

| Manufacturer: |

American Lab & Systems (ALS) |

|

|

|

|

|

|

|

|

Stationary "UNIVERSAL" Wide Body Aircraft Components Test Stand.

Available in skydrol fluid media, or other fluid applications upon request.

This stainless steel test stand is rated 50 GPM and designed to test: actuators, valves, pumps, hose assemblies and related components to 3000 PSI with a proof test circuit to 10,000 PSI.

This Dual System unit offers 2 test stations each able to provide 0/25 GPM and 0/3000 PSI which may be combined for a total 50 GPM and 3000 PSI flow test.

The pump test circuit is controlled by a "State of the Art" variable frequency drive with standard aircraft adapter pump mount.

This stand consists of three (3) major components:

1. Remote Hydraulic Power Unit including

- Pumps

- Filters

- Reservoir

- Starters

2. Main Console including

- System Controls

- Stainless Steel Work Sink

- Outlet Ports

3. Pump Test

- Drive 100 HP, 0-5000 RPM, 7500 RPM on request

- Work Sink

- Fluid Ports

The test stand is designed to perform functional testing of hydraulic components and pumps.

The Test Stand and Pump Drive modules are hydraulically interconnected and only require connection to electrical power and cooling water for operation.

Both the Test Stand and Pump Drive modules include work sinks that drain to the system reservoir.

All Test Stand indicators are panel mounted behind the work sink. Outlet and return shut-off valve, the cycling valve, static system controls, pump drive pump controls, and emergency shut down control are mounted on a sloping panel in front of the work sink.

The Hydraulic Test System consists of supply, return, cycling, pump drive and supply, and static and dynamic high pressure circuit.

Built in SAFETY FEATURES include:

- Warning Lights

- Filter Condition Lights

- Automatic System Shutdown

- Component Shutdown

- Low boost pressure causes low boost pressure switch to open and shutdown of the main pump drive motor

- Excessive fluid temperature causes temperature switch to close and shutdown of the main pump drive motor

Ask about our Automated Stands or Data Acquisition Systems

| Approx. Dimensions: |

12' long |

|

|

|

|

Units Subject To Prior Sale